General

The FEED MATERIAL is FED into CENTRE of ROTOR and is conveyed to the PERIPHERY through series of BEATER PLATE , thus gradually reducing to find powder. SCREEN DRUM fitted around ROTOR, permits ground material of desired FINENESS to come out of the MILL for collection.

Important Technical Information On Pin Mills

Premium Pin Mill Is A Specially Designed Pulverizer To Deal Efficiently And Economically With A Wide Range Of Materials To Grind Them To Predetermined Fineness From Coarse To Fine Powder Up To 150 Mesh (100 Micron) And Above. The Grinding Operation Is Effected Through Beating, Shearing, Crushing And Auto Collision Of Material. Feeding Is Manually For Small Mills And For Medium And Large Capacity Mills, Either Hopper With Horizontal Gate Valve With Rack & Pinion Is Provided Or Screw Feeder With Variable Speed Drive. This Will Give Uniform And Controlled Feed Into The Mill, Pin Mill, Pin Mill Pulverizer, Pin Mill Manufacturer In India.

Salient Features

The Internal Design

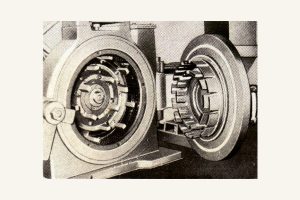

Main Body Of Premium Pin Mill Consists Circular Husing To Accommodate Rotor With Pins, Screen Drum And Main Shaft With Nut. Housing Has Broad Base For Mounting. Other Half Is In The Form Of Hinged Door With Opening In Center & Round In Shape And Have Stationary Casted Rings Mounted On Inside Of Door. The M.O.C Is Either M.S Or S.S In Casted Form. Large Pin Mills Are Fabricated From Thick Plates And Are Welded And Streesreleaved.

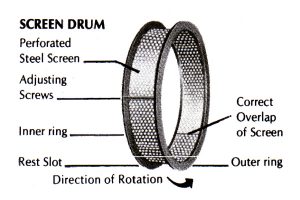

The Drum Is Designed To Facilitate Required Mesh Size Screen To Be Fitted Around The Rotor. The Screen In Semi Circular (Two Halves) Form Is Held In Place By Outer And Inner Rings. The Rest Slot Decides The Location And Helps In Fixing The Screen Drum And Prevents From The Circular Motion. Correct Overlap Of Screen Avoids Leakage. The Adjusting Screws In The Rings Fix The Screen Drum Properly.

This Consists Of Several Concentric Rings Of Beater (Pin) Plates Arranged Around The Shaft With Heavy Duty Ball Bearing Mounted In Heavy Duty Bearing Housing With Adequate Arrangement For Lubrication.

The Pins In The Rotor Are Generally In "L" Shape And Are Riveted On Plate. The Number Of Such Pins Depend Upon The Rotor Diameter". The Shape Of Pin Can Be In Form Of Studs (Round Pins) Also. Even Stator Rings Can Be Provided With Round Pins For Better Grinding Efficiency. Special Type Of Pins And Its Geometry Shape And Location Will Improve Grinding Efficiency Further. There Pins Are Made Out Of Forged Steel Or Forges Stainless Steel.

These Baloons Are Made Out Of Thick Cloth Bag And Is Fitted At The Top Of Chamber / Collection Bin. It Allows To Escape Air From The System And Avoids Back Pressure.

Small Size Pin Mill Mounted On Cabinet

Models Ppm - 06,08 & 10 Are Designed For Small Capacity Output And Usually Are Fed Manually Through Feed Tray And A Collection Cabinent With Baloon. The Ground Material Is Falls In To Cabinet. The Mill Is Stopped And Material Is Collected.

| MODEL | DIA mm | H.P. | RPM | SPACE REQUIRED L X B X H in mm | CAPACITY Kg./Hr |

| PPM-06 | 160 | 1 | 2500/5000 | 500 x525 x600 | 5 – 50 |

| PPM-08 | 210 | 2 | 2500/4500 | 550x575x700 | 25 – 200 |

| PPM-10 | 260 | 3 | 2000/4000 | 575x625x800 | 55 – 400 |

Medium Size Pin Mill Mounted On Stand

Models Ppm - 12, 20 & 25 Are Medium Capacity Pin Mills Having Capacity Ranging Between 200kg/Hr To 1000kg/Hr Depending Upon Material And Fineness. Ideal For Medium Hard Materials, These Pin Mills Are Mounted On Fabricatedstand And Are Usually Bottom Open Type (B.O.T). For Collection Of Pulverized Material, Collection Bin Is Put Below Mill. For Avoiding Dust Formation, Cloth Bag Is Tied Up In The Outlet Of Mill, Which Opens Into Collection Drum.

| MODEL | DIA mm | H.P. | RPM | SPACE REQUIRED L X B X H in mm | CAPACITY Kg./Hr |

| PPM-06 | 310 | 5-7.5 | 2000/4000 | 675 x700 x1000 | 105 – 600 |

| PPM-08 | 480 | 10 – 20 | 1500/3000 | 1400x1000x1350 | 205 – 2000 |

| PPM-10 | 628 | 20 – 30 | 1200/2400 | 2100x1400x1600 | 300 – 3000 |

Large Size Pin Mill With Screw Feeder

Premium Pulman Have Designed, Manufactured And Supplied Large Pin Mill Pulverizer, Pin Mills Up To 1000mm. Dia With 100h.P Motors And Above.

These Mills Are Manufactured In M.S / S.S Construction. They Are Supplied With Screw Feeder With Variable Speed Drive For Regulated Feed.

Ideal For Medium Fine And Coarse Material. The Design Of Rotor Is Modified And Pin Is Designed To Facilitate The Same.Medium Hard, Fiberous And Free Flowing Materials Are Ground Very Comfortably. The Size Of Hole In The Screen Drum Is Selected As Per Requirement Of Mesh Size Of End Product.

Generally For Large Outputs, Collection Is Done Pneumatically With The Help Of Blower. The End Product

Is Collected In Cyclone Collector. Fines Are Collected In Fabric Type Dust Collector. Output Material Collection Is Done By Screw Conveyor.

For Very Fine Powder, Premium Pin Mills Are Designed With Classifier System.

The Installation Of Such Large Pin Mills Have Hopper Of Appropriate Size, Screw Feeder, Magnet, Rotating Grinding Plate, Stationary Grinding Rings, Screen Drum, Discharge Outlet And Main Shaft Mounted On Bearing Housing.

These Mills Are Mounted Either On Platform Or In Thesystem Structure. Out Put From Mill Is Conveyed Either Mechanically Or Pneumatically For Further Process.

| MODEL | DIA IN mm | H.P | RPM | SPACE REQUIRED ( IN mm) | CAPACITY Kg./Hr | ||

| L | B | H | |||||

| PPM-30 | 750 | 40 | 1000 /2000 | 2200 | 2000 | 1800 | 500 – 5000 |

| PPM-36 | 900 | 75 | 800 / 1600 | 2400 | 2300 | 2000 | 800 -8000 |

| PPM-42 | 1000 | 100 | 750 / 1800 | 2600 | 2600 | 2200 | 1000 – 10000 |

Pin Mill With In-Built Classification System

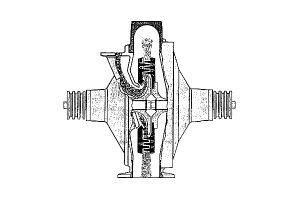

Pin Mills Are Manufactured With Whizzer Cone And Whizzer Blade. The Blower Is Mounted On The Same Shaft ; Pneumatically Material Is Taken Through W H I Z Z E R T O C Y C L O N E Collector.

These Pin Mills Have Inbuilt Classification System With Gap Plate Arrangement And Classifier Fan Mounted On The Same Shaft. Mills Are Supplied With Cyclone Separator / Dust Collector / Pulse Air Jet Dust Collector Depending Upon The Characteristic Of Material Pin Mill Manufacturer.

Other Versions Of Pin Mill

The stator and rotor discs are fitted with round pins. These pins are riveted on plates. The no. of pins. Pitch, etc. is designed to suit the g r i n d a b i l it y a n d fineness required.

These pin mills have both discs rotating either in one direction or opposite direction. The relative speed is very critical and is maintained within design limits. The discs are rotated by two independent motors. These pin mills are without screen and produce fine particle size.

Pin mills are supplied with blower, cyclone collector with rotary air lock valve, and fabric bag type dust collector.

| Aluminum | Ceramics | Glue | Plaster | Spices |

| Animal Charcoal | Cereals | Golden Ore | Powder of Sweet Potato | Starch |

| Ayurvedic herbs & leaves | Charcoal Powder | Graphite Antimony | Powder Soap | Sugar |

| Bakelite Pigments | Clay | Lithopone | Pyrethrum flower | Tapioca root |

| Bark | Coal | Maize | Quick lime | Tark |

| Barley | Corn | Mehendi leaves | Resin | Tea |

| Bone powder | Dried Grass | Oyster shells | Rice Powder | Tobacco leaves |

| Bran & husk Powder | Dye-stuff | Paints | Salt | Tomato |

| Celluloid | General manure | Paper Powder | Soya bean cakes | Wheat |